Facility

ZBCX four manufacturing facilities are strategically located to meet the various high pressure aluminum die casting, aluminum gravity casting, CNC machining and finishing needs of a wide variety of markets. Every division has expertise in producing high quality aluminum die castings requiring close tolerances, pressure tightness, good surface finish, and various secondary operations.We offer full service Die-Cast solutions. Our strength includes die design, die making capabilities, engineering, melting and in-house alloying, die maintenance, casting, finishing, machining, and assembly.

Grand Total Manufacturing Space:

4,0000 square meter

Alloys Cast:

ADC-12, ADC-10, A356,A380,A360

AlSi11Cu3, AlSi12, AlSi9Mg, AlSi7Mg,

Cast Capabilities:

Aluminum die casting ; Aluminum gravity casting ; Zinc Die Casting ;

By Weight

0.05kg to 20kg

Castings are made from precision steel molds:

Single cavity molds

Multi-cavity molds of the same part

Family cavity molds of different parts

CNC Machining:

CNC machining centers and lathes, as well as dedicated and flexible type machining centers.

Secondary Processes:

Various in-house and contracted secondary processes including shot blasting, deburring, sand blasting, powder coating, painting and anodizing.

Industries Served:

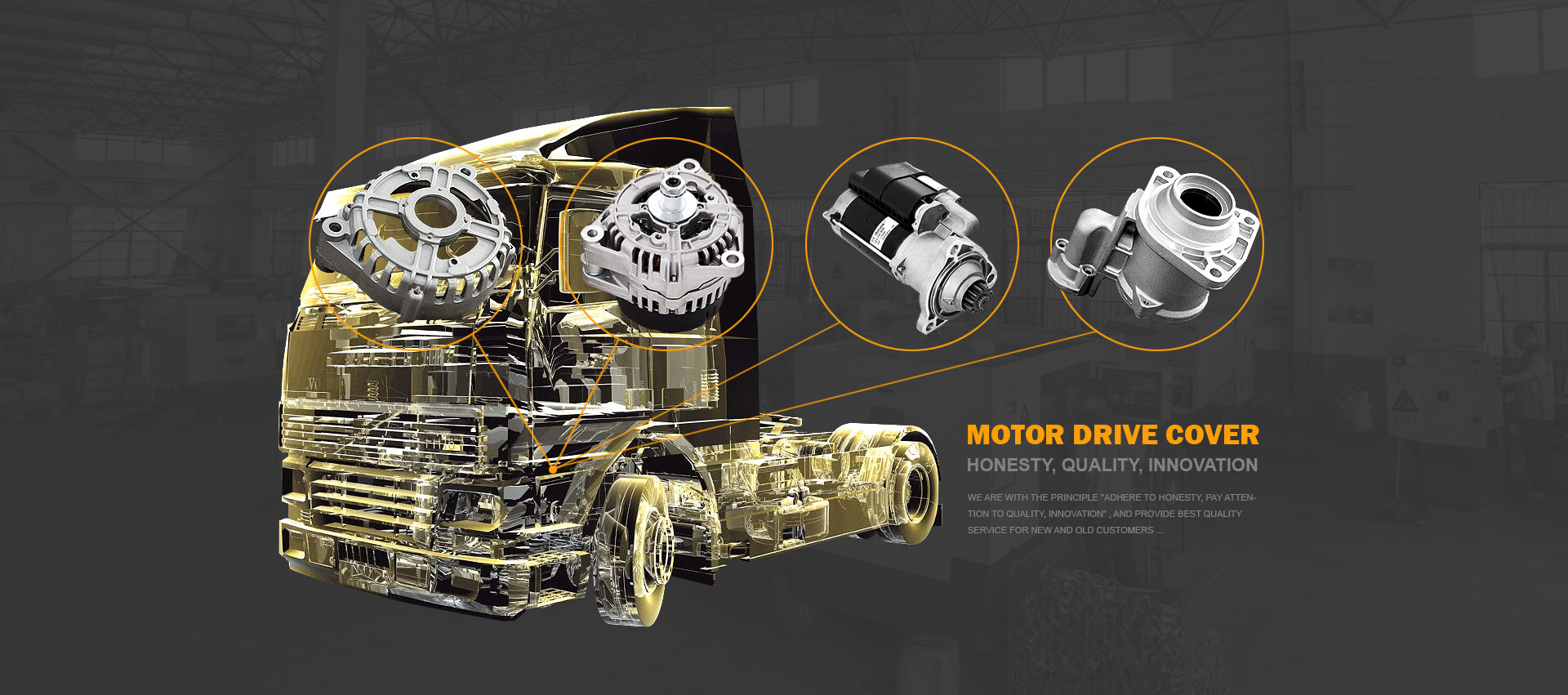

Automotive

Communications

Green Technologies

Heavy Duty

Commercial Vehicle

Industrial

Medical

Power Equipment

Utilities