Services

Aluminum Gravity Casting

Aluminum gravity casting can also be referred to aluminum gravity die casting,aluminum metal mold gravity casting or aluminum permanent mold casting.

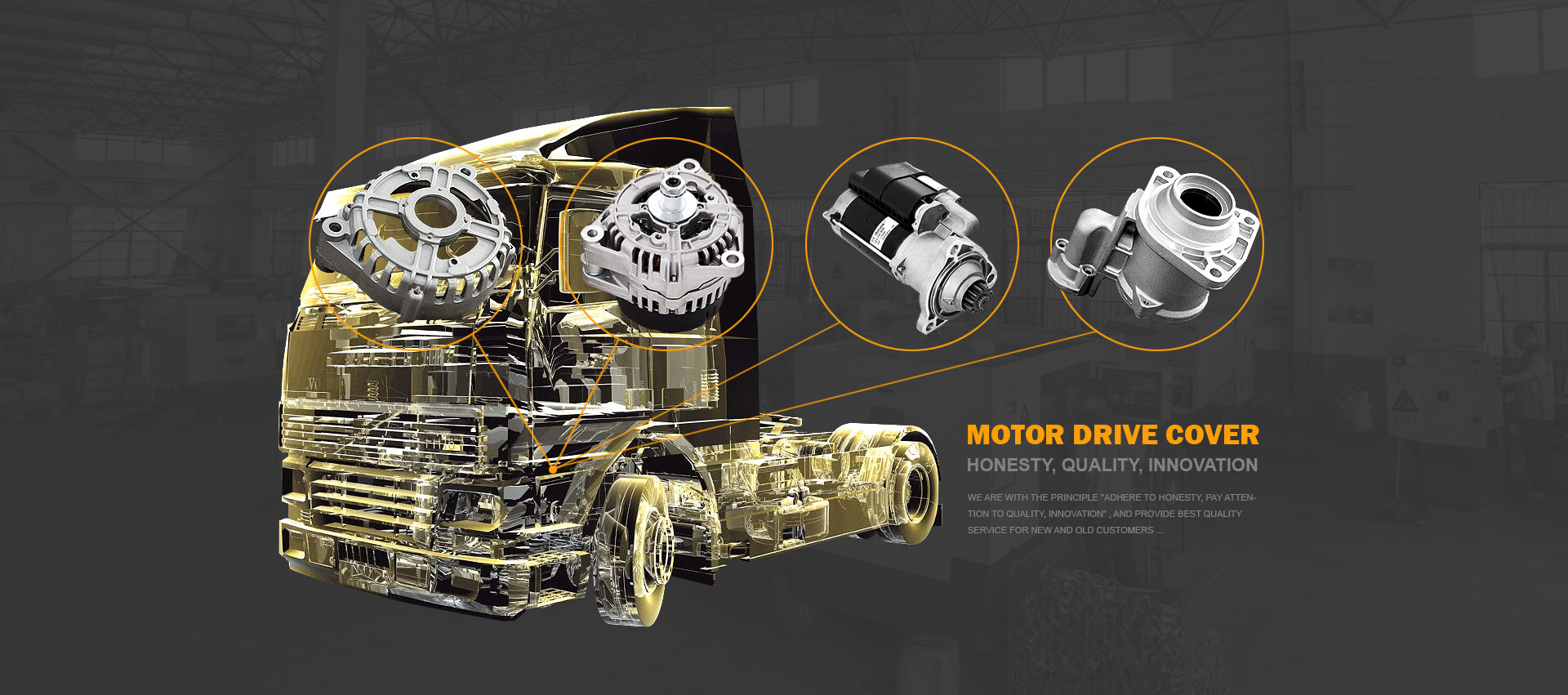

ZBCX are able to produce quality aluminum gravity die castings for a range of industries, including High Horsepower Diesel Engines, Defence, Gas Turbines, Machine Tools, Compressors, Pumps, Valves, Medical Equipment, Light Construction Equipment, Articulated Trucks, Photo Imaging and Printing.

Aluminum gravity casting process

Aluminum gravity casting likes other common ways of casting. The melted aluminum alloy is poured into the mold by means of gravity-fed. Though pouring rate is relatively low, yet the metal mold produces rapid solidification.

Aluminum gravity casting uses the force of gravity, to fill a permanent mold, or die, with molten material. It does not use the high-pressure method to form the casting. It will ensure that there will not be any clusters formed during this process.

The method has advantages like cost effective, good quality, and process control over other casting techniques. Aluminum gravity casting is done in ceramic molds, permanent casting, and sand and also in investment or lost foam casting.

Advantage of aluminum gravity casting

A.Good mechanical property compared with aluminum die casting

Aluminum gravity casting parts have excellent mechanical properties compared with that of die casting parts. Because aluminum gravity casting parts has very lower porosity than aluminum die casting parts. ALuminum gravity castings are generally sound, provided that the casting aluminum alloys used exhibit good fluidity and resistance to hot tearing. Besides,mechanical properties of permanent mold castings can be further improved by heat treatment.

B.High volume production compared with sand casting

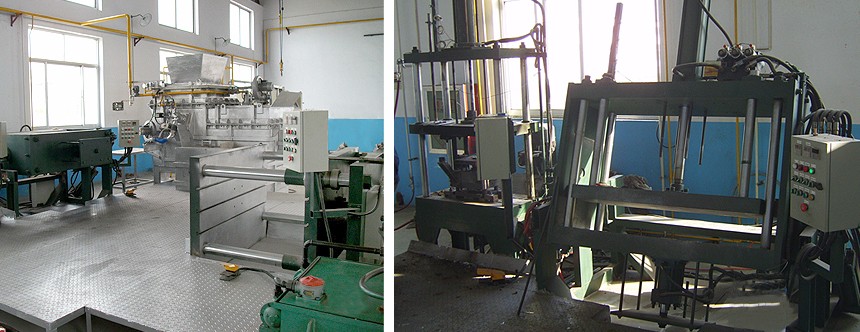

Aluminum gravity casting is suited to high-volume production. Compared with aluminum sand casting process,aluminum gravity casting process uses permanent mold avoid forming shell every time,thus can save a considerable time for casting process. Furthermore, aluminum gravity casting process can be assisted by gravity casting machines, which can increase the production capacity dramatically.